Static electricity

What is static electricity?

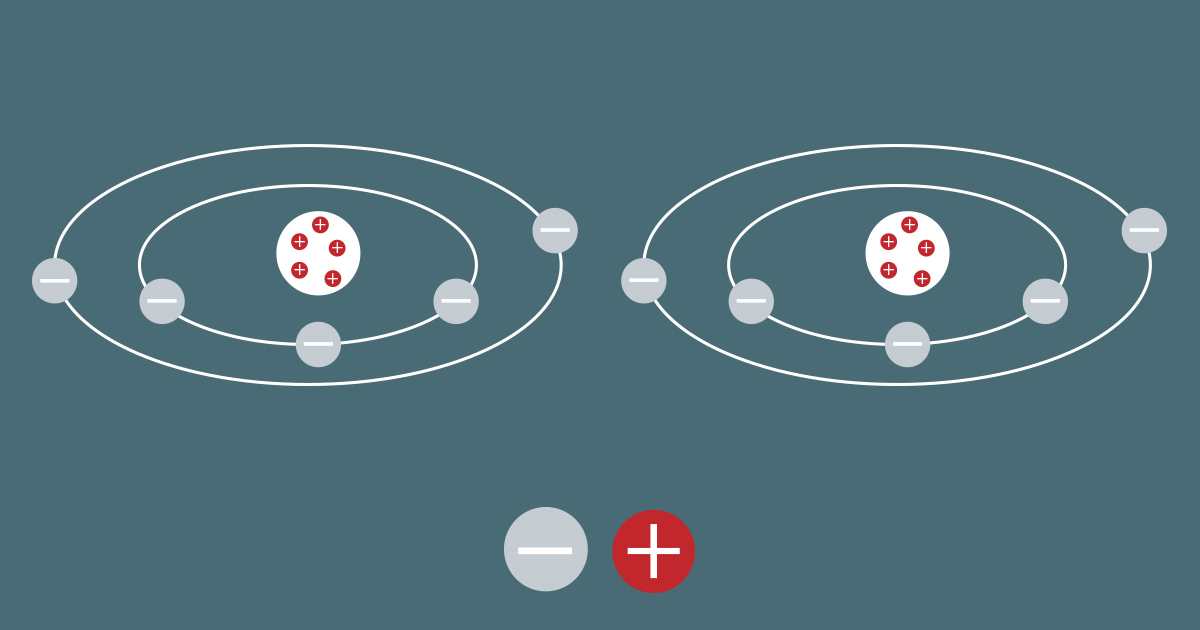

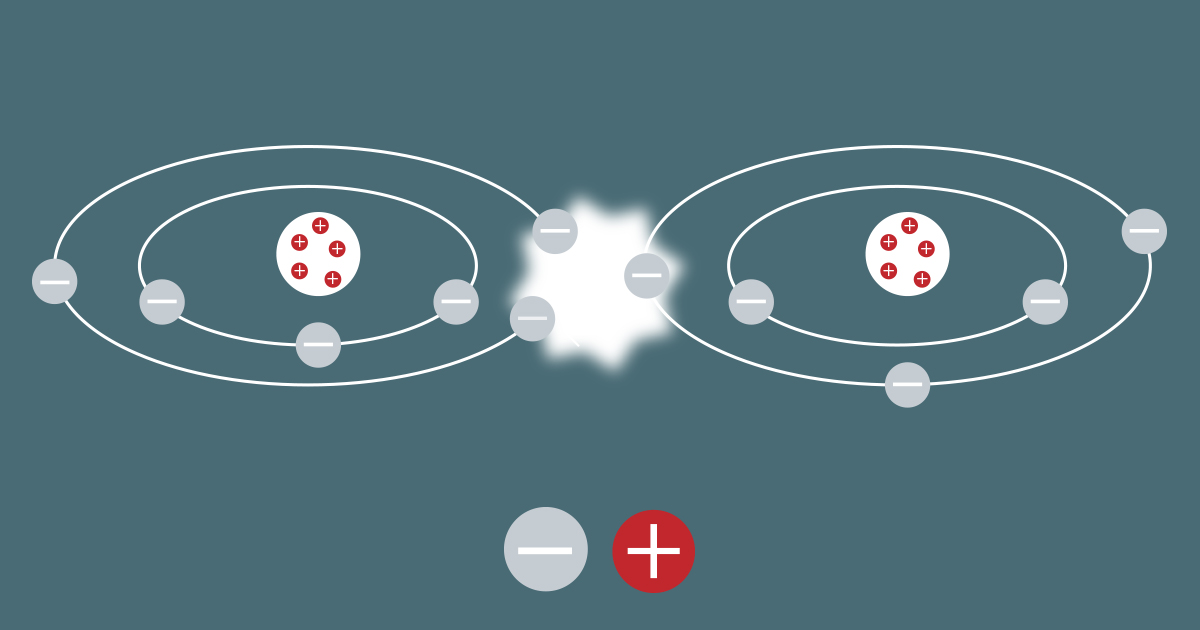

Basically, static electricity is an imbalance in the electric charges in a material. The imbalance – i.e. the loss or addition of electrons – occurs when two surfaces come into contact, interchanging electrons.

One of the main causes of static charge is the triboelectric effect, in which certain materials become electrically charged through contact. In essence, a thunderstorm is due to electrostatic charges building up between clouds and the ground.

Static electricity builds up during contact between materials as they exchange valence electrons. However, air humidity makes the air more conductive, so it can absorb and more evenly distribute excess charges.

Static charge: Valence electrons change places, creating an imbalance

As a result, in an environment with high air humidity, objects will not hold static charges quite as well.

| Voltage build-up in everyday events (kV) | |

| Walking across a carpet | 30 |

| Picking up a polythene bag | 20 |

| Walking on a vinyl-tiled surface | 15 |

| Working at a bench | 5 |

This table shows the voltage build-up in everyday events - and the difference relative humidity (RH) makes. Relative humidity above 40% does not eliminate static electricity, only allows it to dissipate harmlessly. Source: electronics-notes.com

Why humidity matters

Water is a great conductor of electricity. An electrically charged object will therefore relieve its electric charge when the air is humid, reducing the risk of a sudden electrostatic discharge (ESD).

However, compared to metals, the electrical conductivity of pure water is surprisingly low:

| Table of conductivity (S/m) | |

| Pure water (RO) | 5.5 × 10-6 |

| Aluminum | 3.5 × 107 |

| Steel | 6.21 × 106 |

Electrical conductivity is measured in Siemens per meter (S/m) or A/V = 1/W). The combined dispersive effect in water vapor means that the ESD in moist air will dissipate rapidly.

Moisture does not prevent ESD, it just absorbs it better

In air with low relative humidity, the imbalanced charges will only even out their difference in charge by coming into contact with another conductor. In air with higher humidity levels, the moisture in the air provides a medium for the charge to release in a more harmless fashion.

Essentially, what happens is that the individual water molecules possess a much higher conductivity than surrounding air, so the charge will be released to the water in the air. The electrostatic discharge still happens, in other words, but is spread out across countless water molecules or droplets.

In this way, high charges do not occur when relative humidity is above a certain point.

Electrostatic discharges as a real risk

In production environments, static electricity will always build up somewhere; no technology can prevent this from happening. It is the location of the discharge (ESD) that causes problems.

In electronics production, even the smallest ESD can damage semiconductors, effectively destroying the product.

Even low levels of ESD can have a huge impact on sensitive electrical devices, impacting yield, quality and reliability resulting in a huge cost to manufacturers.

No shock: Static electricity as a problem-causer

But the risk of shocks due to ESD is not the only problem connected to static electricity – or, to be specific, the build-up of an imbalance in electrostatic charges on the surfaces of objects.

At a relative air humidity below 40%, the risk of static electricity build-up is strongly increased.

For an electrostatic charge to build, friction contact is essential: Two materials must, as it were, rub against each other, exchanging valent electrons. Most production environments have all the ingredients necessary for static electricity to form: An environment with high local heat sources will cause air humidity to drop.

The solution is to ensure a relative air humidity no lower than 40% - in fact, closer to 60% is ideal in most cases. This is done by supplying the air with sufficient humidity at all times.

How to counter ESD

In production technology, the prevention of ESD is a standard discipline and one that is taken very seriously. The protection against ESD is typically divided into passive and active measures – passive measures being e.g. insulating floor mats, grounding of personnel and tools and so forth.

Controlling the air humidity is an active measure against ESD. Once the optimum humidity level has been reached – typically between 40 and 60% RH – the moisture in the air is sufficiently high to allow electrostatic charges to be released harmlessly into the air. At the same, at such a humidity level moisture will also settle on surfaces to form a conductive layer, giving further protection.

The installation of a high-pressure air humidifying system is one of the most cost-effective methods for improving productivity and reducing ESD risk available.

See how we’ve done it for others

Airtec® has decades of experience in planning, installing and servicing air humidifying systems – take a look at our case stories here.